- +86 13980992861

- bs_refractory@163.com

- Circulation Industrial Park, Wangyang Town, Renshou County

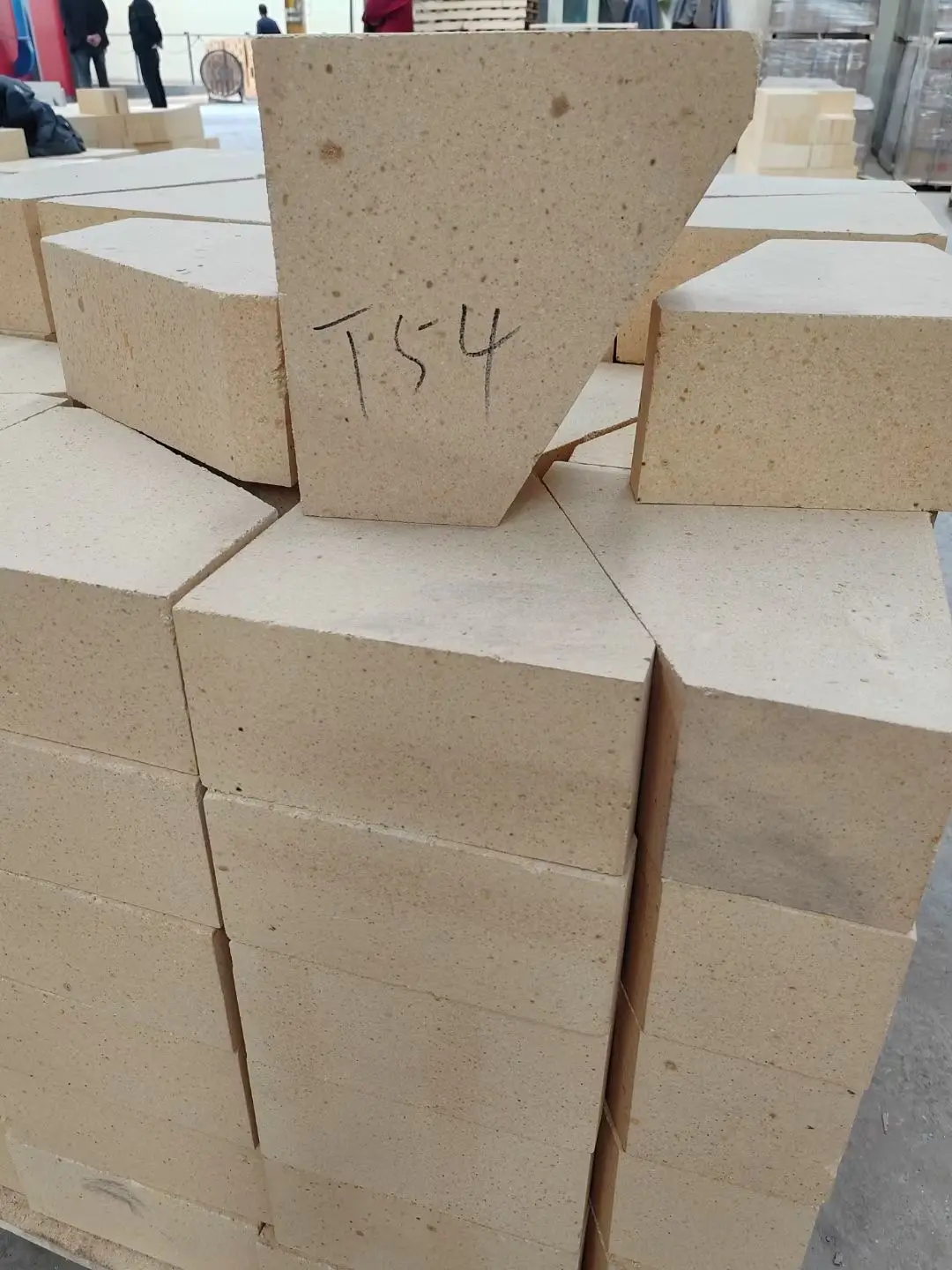

kiln car bricks

Size: customized

Material: high aluminum/clay

Material stress

Refractory bricks are placed inside the kiln car enclosure to act as a thermal insulation seal, protecting the kiln car from high temperature and highly corrosive environments and extending the service life of the kiln car. The green bricks are stacked on the upper part of the refractory bricks, and the load-bearing pressure is calculated according to the method of stacking 12 layers of standard bricks (size: 240×115×53; unit weight 2.63kg). The kiln car travels due to the thrust of the hydraulic jacking car. Due to the large instantaneous pressure, the stress-bearing surface is the kiln car channel steel and channel steel. When the kiln car collides, the refractory bricks and refractory bricks still have about 5 ram.

In addition, the refractory bricks are combined in a staggered manner, which not only ensures the isolation between the upper and lower parts of the kiln car, but also avoids the collision of the refractory bricks and the angles of the refractory bricks.

use: Kiln car refractory bricks must ensure high temperature resistance and corrosion resistance. Therefore, burnt gemstone refractory bricks (-45% AL203) and high alumina refractory bricks are commonly used in tunnel kilns.

(≥55%AL203), mainly because of its good thermal stability, fire resistance temperature 1580-1770°C; pressure resistance 25-58MPa.

Reviews

There are no reviews yet.